15

2025

-

09

Low-carbon intelligent innovation, new quality leadership | Rubber Products Industry Members' Conference and Technology Development Forum successfully held in Jiyuan

Source:

Release time:2025-09-15 11:57

9 From October 10 to 12, 2025, the China Rubber Industry Association Rubber Products Branch Member Conference and Industry Technology Development Forum was successfully held in Jiyuan, Henan.

This conference was hosted by the Rubber Products Branch of the China Rubber Industry Association, themed "Low Carbon Intelligent Innovation, New Quality Leadership," gathering more than 160 participants including council members of the branch, member units, expert group members, research institute experts, and upstream and downstream suppliers of materials and equipment. The forum deeply discussed core topics such as product innovation, green development, and digital intelligence of enterprises in the rubber products industry, jointly envisioning the industry's future.

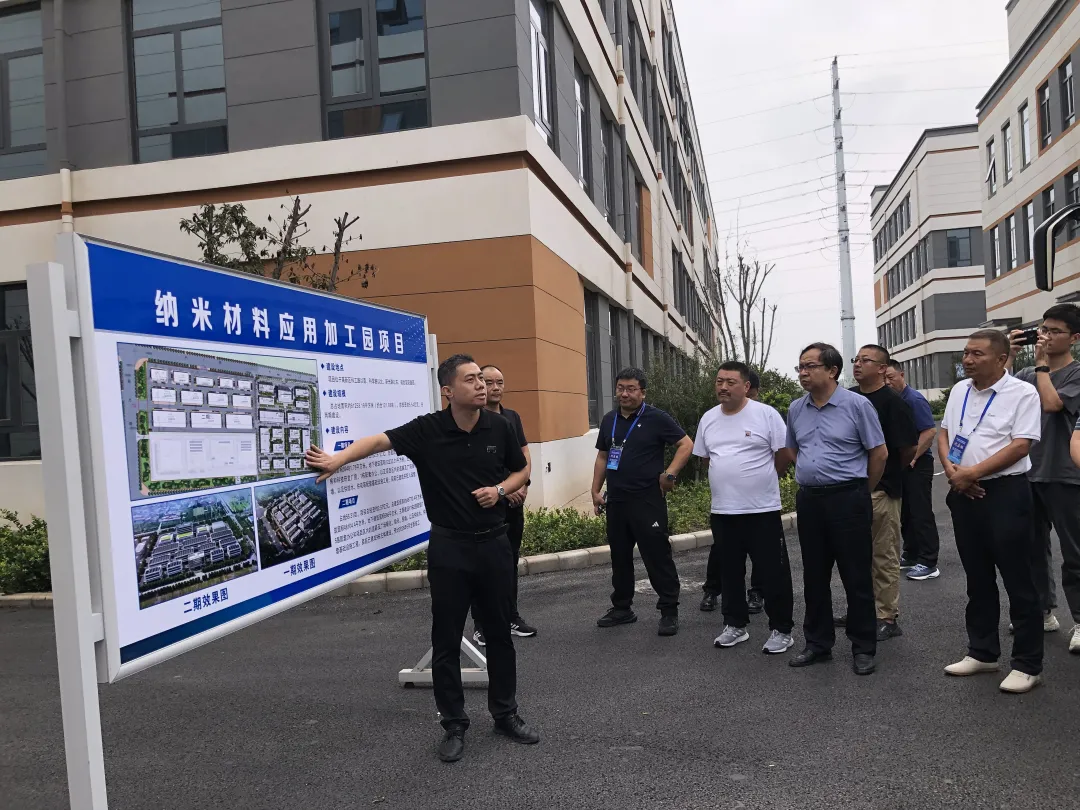

At the beginning of the meeting, Wang Xiaofei, a member of the Party Leadership Group of the Management Committee of the Jiyuan Production-City Integration Demonstration Zone in Henan Province and Deputy Mayor of Jiyuan City Government, delivered a speech. He stated that Jiyuan, as the birthplace of the spirit of Yu Gong moving mountains and a demonstration zone for full-area production-city integration, has formed leading industrial clusters such as non-ferrous metals and steel, with six first-level enterprises and two China Top 500 enterprises. Currently, Jiyuan is focusing on cultivating strategic emerging industries such as nanomaterials, building a national important nanomaterial research and production base and rubber products industrial base, planning to construct a 1,408-acre rubber products industrial park, and sincerely inviting entrepreneurs to invest and develop businesses.

Zhang Zhijun, Chairman of Jiyuan Hongxin Rubber Composite Materials Technology Co., Ltd., delivered a speech. He introduced that Hongxin Rubber focuses on the research and development of nano rubber composite materials technology. Its wet mixing technology solves the problems of high energy consumption and pollution in traditional dry mixing. Currently, the company has completed and put into production a 10,000-ton-level natural rubber and white carbon black wet mixing production line. A 20,000-ton full-formula wet mixing production line is under construction, expected to be completed by the end of September and officially put into production in November. In the future, the company will continue to expand capacity and is committed to building a nano rubber composite industry chain with an output value exceeding 10 billion yuan. It hopes to promote development together with industry colleagues through this conference.

Lei Changchun, Vice President and Secretary-General of the China Rubber Industry Association, delivered a speech. He introduced that the China Rubber Industry Association is a national-level social organization composed of a complete upstream and downstream industrial chain of the rubber industry, with 14 professional branches. The rubber products industry, as an important part of the traditional industrial chain, has a wide range of product categories and coverage. According to data from 337 enterprises collected by the association, from January to July 2025, the rubber industry as a whole achieved growth. Among them, 68 key rubber products enterprises performed well, with main operating data such as current price industrial total output value, sales revenue, export delivery value, and profits all increasing year-on-year from January to July.

Looking back over the past year, the global economic landscape has undergone profound changes, with industrial and supply chains facing restructuring pressures, and green low-carbon transformation becoming urgent. Lei Changchun emphasized that the traditional growth model is no longer sustainable. Only by focusing development on technological innovation and unswervingly pursuing high-end, intelligent, and green development paths can we gain initiative and advantage in global competition. He called on the industry colleagues to work together, embracing change with an open mind and driving development with innovative spirit, to jointly write a new chapter of high-quality development for China's rubber products industry, as rubber, though small, relates to national economy and people's livelihood, and ordinary products support thousands of industries.

At this conference, the China Rubber Industry Association released group standards for rubber products, including: T/CRIA18006-2025 "Drainage Pipe for Motor Vehicle Sunroofs," T/CRIA18007-2025 "Technical Specification for Commercial Vehicle Chassis Air Spring Assembly," and T/CRIA18008-2025 "Energy Consumption Limits for Unit Products of Mixing Rubber." Relevant leaders presented certificates to the standard drafting units at the meeting.

Song Yan, Secretary-General of the Rubber Products Branch, reported on the economic operation and main work of the industry for 2024-2025.

According to statistics from 62 member enterprises of the Rubber Products Branch of the China Rubber Industry Association, In 2024, the industrial total output value increased by 9.68% year-on-year; the export product delivery value increased by 10.85% year-on-year, accounting for 15.78% of the industrial total output value. Sales revenue increased by 12.7% year-on-year; profits increased by 23.13% year-on-year. In the first half of 2025, among 68 member enterprises surveyed by the branch, the industrial total output value increased by 18.27% year-on-year; export product delivery value increased by 8.57% year-on-year; export product delivery value accounted for 12.27% of the industrial total output value. Sales revenue increased by 21.26% year-on-year; total profits increased by 21.39% year-on-year, maintaining stable growth in the industry. Secretary-General Song Yan analyzed the phenomenon that the association's statistical data is better than the industry average.

In 2024-2025, the Rubber Products Branch, focusing on industry development needs, orderly promoted multiple key tasks. In terms of meeting organization, the branch held an industry council meeting concurrently with the China Rubber Industry Association annual meeting in March to summarize last year's work and clarify this year's plans. Regarding expert resources and standard construction, a high-end expert group meeting was held to exchange industry information and add new members. Besides the three group standards issued at this conference, the branch is also advancing the drafting of standards such as "Energy Consumption Limits for Unit Products of Rail Vehicle Suspension Rubber Products," "Rubber Internal Expansion Rings for Trenchless Pipeline Repair," and "Rubber Vibration Isolation Pads for Floating Floor Slabs." In terms of industry services and planning guidance, the branch will promote work related to the 15th Five-Year Plan; strengthen connections with related industries; provide technical consulting services to enterprises to help solve technical problems in production and operation; actively recruit new members to expand membership and enhance industry cohesion. Additionally, the branch strengthens website system construction through an information platform to provide industry information and services to members; addressing the weak statistical work caused by the wide variety of rubber products and limited sample collection, it calls on member enterprises to participate in statistics to support industry development with data. Song Yan stated that the smooth progress of work depends on the support of member enterprises and related units, and the branch will continue to improve service quality and assist industry development in the future.

At the forum, several experts and scholars gave reports on cutting-edge industry technologies.

Niu Lihong, Deputy General Manager of Jiyuan Hongxin Rubber Composite Materials Technology Co., Ltd., delivered a report titled "Wet Mixing Technology and Application Prospects of Green Zero-Carbon Nano Composite Rubber." Currently, traditional mixing processes have problems such as high energy consumption, heavy pollution, low efficiency, and poor dispersion, which cannot meet the needs of green and efficient development. Hongxin Company pioneered the development of water-based full-formula wet mixing technology, mixing latex, nano fillers, and additives in a water-dispersed form at room temperature, followed by flocculation, dehydration, and drying, achieving a full process with no "three wastes" emissions and continuous production.

This project integrates five core processes: surface functionalization of nano fillers, emulsification of solution polymerized rubber latex, microencapsulation of sulfur, independent core equipment, and low-temperature continuous production line, overturning traditional dry mixing. Compared with traditional processes, the production cycle is shortened by one-third, energy consumption is reduced by more than 50%, the full-chain carbon emissions approach zero, significantly improving rubber performance and environmental protection levels. This technology is suitable for various military and civilian rubber products and is a key technology for the rubber industry to move towards green, efficient, and intelligent manufacturing.

Shangguan Wenbin, Professor at the School of Mechanical and Automotive Engineering, South China University of Technology, delivered a report titled "Design and Performance Study of Air Springs." The report introduced the structural characteristics of air spring suspension systems, the structure and advantages of air springs, design requirements, stiffness design methods, and fatigue design methods of air springs, several research issues during use, as well as bending and abnormal noise problems of air springs during use.

A report titled "Environmental Formulation and Long-life Formulation Design of Products under the Background of the New Energy Era" was presented by Song Shijie from Henan Crosslinking Research Institute. He introduced that under the global "carbon neutrality" goal, China's "dual carbon" strategy, and the EU Carbon Border Adjustment Mechanism (CBAM), the demand for new energy vehicles is continuously rising. Compared with traditional fuel vehicles, new energy vehicles' power systems show trends of "electrification, high voltage, and integration," prompting automotive rubber products to upgrade from traditional "oil resistance and high temperature resistance" to "medium resistance, high durability, insulation, and lightweight," with design optimizations in environmental formulation and long-life formulation. The company's R&D team combined the mechanisms of vulcanization crosslinking systems and anti-aging systems in products. The environmentally friendly vulcanization system meets basic physical property requirements while reducing product odor issues, and through the synergistic effect of anti-aging agents, further enhances the product's high-temperature aging resistance.

A report titled "Innovative Application of Cellulose Nanocrystals in Rubber Products" was presented by Sun Peizhu, General Manager of Qingdao Aiboer Management Consulting Co., Ltd. The report introduced the application of cellulose nanocrystals in rubber products, with background involving the EU carbon tariff and China's dual carbon strategy, emphasizing the importance of bio-based materials in reducing carbon emissions. Cellulose is widely sourced, with 70% from non-wood materials, possessing advantages such as biodegradability, non-toxicity, and easy processing, and can be used to make separation membranes, aerogels, etc.

Cellulose nanocrystals have diverse applications in rubber products. As a reinforcing agent, they outperform white carbon black, improving vulcanized rubber hardness, tensile strength, etc.; as a dispersing aid, they enable more uniform dispersion of sulfur and other additives; as a stabilizer, their vulcanization effect surpasses traditional stabilizers; they can also carry functional additives and serve as bio-based photonic materials exhibiting structural color. With expanded applications, their cost advantages will become more apparent, and the application prospects are broad.

A report titled "China's Rubber and Silicone Machinery: Value Empowerment and New Industry Development Trends" was presented by Zhu Xiaoling, General Manager of Guangdong Xinjingli Precision Machinery Co., Ltd. The report analyzed the development trends of China's rubber and silicone machinery industry; discussed efficient paths to sustainable development through automation and green technologies; and shared insights on achieving intelligent production of rubber and silicone products through intelligent interconnection technology and big data analysis.

A report titled "Construction of Multi-constitutive Models and Energy Absorption Simulation Research of TPEE Elastomers" was presented by Huang Youjian, Director of the Simulation Research Department at Zhuzhou Times New Material Technology Co., Ltd. This report focused on the simulation research of thermoplastic elastomer (TPEE) buffers. TPEE materials combine the mechanical properties of hard segment plasticity and soft segment elasticity. As the "third generation rubber," they have advantages of high load-bearing capacity, corrosion resistance, and compliance with the "dual carbon" goals.

The core goal of TPEE buffer simulation is to solve the challenge of simulating the mechanical behavior of TPEE during manufacturing and application. This study proposed a solution for constructing multi-constitutive models, accompanied by an elastomer large deformation mesh method, to simulate compression, energy absorption, and impact behavior of TPEE buffers and assess product reliability, providing a reference for simulation research of similar elastomer materials.

A report titled "Multiscale Study and Life Prediction of Rubber Material Aging Behavior" was presented by Li Hongchun, Researcher at Xi'an Aerospace Power Research Institute.

A report titled "Performance Requirements and Development Trends of Rubber Products for New Energy Vehicles" was presented by Zhu Yi, Senior Director of Materials R&D at the Original FAW R&D Institute and Director of Changchun Branch of Huami New Materials Technology Co., Ltd. The report overviewed the application of rubber products in new energy vehicles, explained the performance differences and special requirements of rubber products in new energy vehicles compared to traditional vehicles, and discussed future trends.

A report titled "Capital Value Discovery of Technological Innovation" was presented by Wang Shengjun, Senior Partner at Kangda Law Firm. China has the world's largest, most complete, and most competitive industrial chain, benefiting not only from demographic and market dividends but also from the support of technological innovation.

Patents, software copyrights, technical know-how, and other core assets of enterprises are important. They can realize value discovery and recreation through means such as capital contribution, enterprise listing, data asset transactions, and RWA token issuance, becoming anchors for enterprise financing and sustainable growth, helping enterprises break free from "involution" and embark on the broad path of transformation, upgrading, and high-quality development.

A report titled "Structural Regulation of Nano-silica and Its Application in Silicone Rubber" was presented by Liu Peisong, Deputy General Manager of Henan Haiborei Silicon Material Technology Co., Ltd. Silica is a key foundational material for high-performance manufacturing industries. Nano products have long relied on high-cost vapor-phase processes, while liquid-phase products face structural issues limiting their application in high-end fields. The research team from Henan University solved the dispersion difficulty of nano-silica in organic media at the source by grafting functional groups onto the surface of nano-silica, endowing the material with more functionalities and breaking through the technical bottleneck of producing high-performance nano-silica by liquid-phase methods. Haiborei, incubated by Henan University, has built the world's first industrial production line with an annual output of 40,000 tons of high-performance nano-silica by liquid-phase method and has realized the substitution of various imported high-end vapor-phase products.

A report titled "High-quality Rubber Product Standards Leading Industry Innovation Development" was presented by Wang Fei, Secretary-General of the National Rubber Standards Committee (SAC/TC35) and from Shenyang Rubber Research and Design Institute Co., Ltd. The report introduced the standard system in the field of rubber and rubber products; the formulation and revision procedures of government standards (national and industry standards); the formulation and revision procedures of group standards; and the roles and significance of various standards in rubber product production.

The technical forum was chaired by Feng Yun, Chairman of Tianjin Zhonghe Rubber Co., Ltd., and Sun Peizhu, General Manager of Qingdao Aiboer Management Consulting Co., Ltd., respectively.

On the morning of September 12, participants visited the Henan University Jiyuan Pilot Base, Henan Haiborei Silicon Material Technology Co., Ltd., and Jiyuan Hongxin Rubber Composite Material Technology Co., Ltd. to gain in-depth understanding of nano-material pilot R&D, liquid-phase nano-silica production, and wet mixing rubber industrialization, directly experiencing cutting-edge industry technology achievements and laying a foundation for subsequent cooperation.

The successful convening of this conference provided a platform for communication and cooperation in the rubber products industry, clarifying the development directions of greening, intelligence, and high-end advancement.

In the future, industry colleagues will work hand in hand to promote the Chinese rubber products industry toward a new stage of high-quality development.

Key words: